Advance Analysis

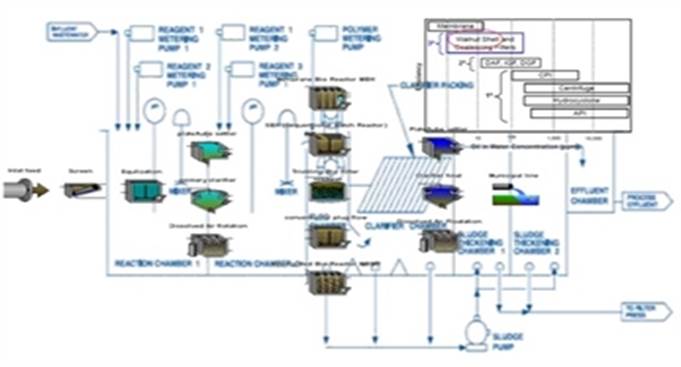

NWD engineers are proficient in utilising advanced simulation programs to create models to help clients better understand and improve target areas of their facilities.

Our process engineering services are focused on delivering high quality design and troubleshooting solutions to industry. The approach is client focused, with time taken to ensure that the scope of work and services required are fully understood prior to commencement of the work

Our modelling experience includes:

- Advance wastewater plant design and optimization using GPS-X

- Hydraulic analysis of piping networks

- Steady state multi-phase models of piping networks to optimise gathering system design

- Dynamic pipeline modelling for optimisation of pipping schedules

- Whole of plant model to validate vendor design with focus on process integration

- Validation of models against plant data

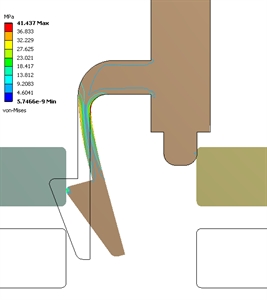

Finite Element Analysis

The use of finite element analysis (FEA) has become common in recent years and is now the basis for most engineering designs. Numerical solutions to very complicated stress problems can now be readily obtained using FEA.

Densep Technologies understands the importance of FEA and recognises that the accuracy of any modelling and solutions is fundamentally reliant on the experience and knowledge of the analyst. Years of practical design and manufacturing experience, combined with extensive use of FEA, enable us to provide unique pragmatic solutions.

Our FEA Services include

- Linear and non-linear static analysis

- Explicit dynamic analysis

- Spectral and harmonic response analysis

- Linear and non-linear steady-state and transient heat transfer analysis

- Transient dynamic behaviour analysis

- Rigid body dynamics

- Fatigue life estimations

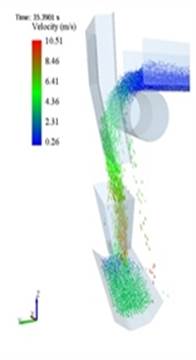

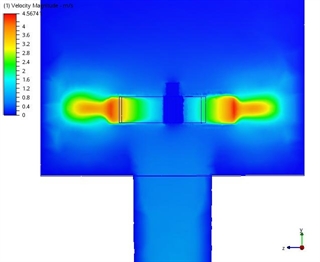

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) Analysis is used to model fluid flows, from highly viscous fluids such as slurries to low viscosity fluids like air. It is used to model simple closed loop systems as well as complex multiphase transient systems in order to determine the behaviour of fluids and the effects this has on the equipment. CFD is used to optimised systems to reduce flow restrictions, cavitation, pressure transients and the like which in turn reduces equipment operating costs.

We undertake CFD studies in:

- Single and multiphase flow analysis

- Free surface flow analysis

- Reacting flow analysis

- Fluid Structure Interactions analysis

- Multiphysics analysis

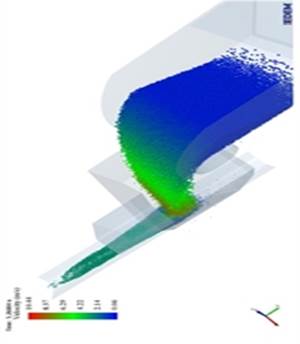

Discrete Element Modeling

Discrete Element Modelling (DEM) has proven to be an extremely effective and valuable tool for analysing and optimising particulate flow in a wide range of bulk material processing and handling operations. DEM can easily model moving boundaries and is used to gain better understanding of particle flow dynamics. The knowledge is then applied to design more efficient equipment, thus improving process efficiency and product quality.

NWD provides DEM analysis services for troubleshooting, design & development of bulk material handling equipments and facilities. Our DEM methodology incorporates a first-principle continuum approach to ensure correct simulation outputs.

NWD has extensive experience in coupling of DEM with Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to investigate specific problems such as froth floatation, cyclone separators, dust control in transfer chutes or the interaction between bulk materials and materials handling equipment, are some